Welcome to DOORspec Integrated Door Systems for the Transit Industry

Based in Canada and located in the Greater Montreal area, DOORspec specializes in the design, manufacturing and development of door systems for the transit industry.

The DOORspec group comprises a team of highly trained engineers. All are experts in the transit field, offering a full range of mechanical, electrical, systems and software engineering knowledge specific to the transit industry. The DOORspec group provides turnkey solutions and product assistance for all door issues relating to trains used for transit. If it’s about train doors, metro doors, light rail doors or any other type of railcar door, at DOORspec, we have all the answers to your train door needs.

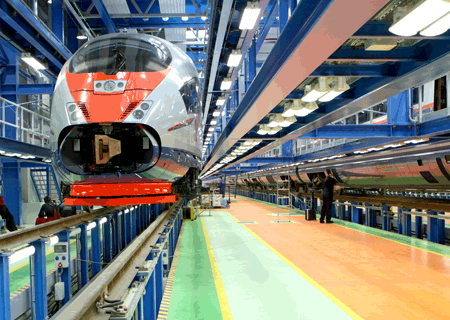

Using all the latest available tools in door innovation, we create rail transit door systems that are technologically advanced, fully functional as to OEM specifications and unique in design and operation. Furthermore, our team of qualified experts works diligently throughout all phases of the project at hand, from conceptual design to the production and manufacturing of all aspects of your order so as to facilitate seamless integration of the various components into your vehicle or station system.

We are dedicated to the support and maintenance of all DOORspec systems from conceptual design as well as throughout the service life of each door system we provide. We have state of the art facilities in La Prairie, Qc, Canada and in Plattsburgh, NY in the United States of America, as well as a network of highly qualified sales agents and support staff based in strategic locations worldwide. DOORspec is a well established company that is focused and specialized in the transit industry, which provides outstanding production, product delivery and customer service from start to finish.

As you browse through our website, you’ll learn more about our transit industry door refurbishment work, our reliability improvement solutions and our system upgrade offerings which comprise our main areas of expertise. At DOORspec, we focus and excel on all aspects relating to train doors. We welcome new projects and project enquiries, as well as specific challenges you may be encountering. Please feel free to contact us with any questions you may have in order for us to assist you further.

DOORspec news…

We’ve opened the door to our new website and are now more than ever, on the rails of innovation.

See what we’re working on right now…

Case ID#179: Upgrading

The client had a problem with the reliability of the door sensitive edge system on a fleet of 30 year old vehicles. We updated the system using the latest type of electrically conductive obstacle sensing door nosing seals. We designed purpose built electronics to interface with the existing door controllers and provide remote malfunction indication.

Case ID#180: Retrofit

This customer had been successfully overhauling the air cylinders used on his door system for about 20 years, a tribute to the long life of the original part. Due to irreparable damage on some cylinders, the client had exhausted his stock of original spare cylinders. We were able to re – engineer and organize the manufacture of a replacement part using most of the same components so that the same consumable items such as seals could still be used.

Case ID#181: Consultation

This client came to us with a problem caused by occasional contact bounce of the safety relays in their vehicle ATC system resulting in doors failing to open. As it was going to be very expensive and take a long time to resolve the ATC issue, we came up with a software solution in the door system software to enable the door system to recover automatically, thus preventing the major service disruption caused by all doors on one side of the car failing to open.